When it comes to selecting the right track system for agricultural equipment, the choice often comes down to friction drive or positive drive tracks. Each system has its own set of benefits and drawbacks, making it important to understand their differences before making a decision.

FRICTION DRIVE

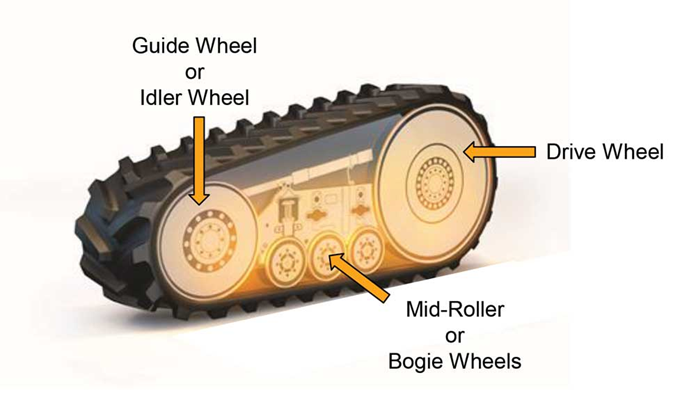

Friction drive tracks are the most common type used in general agriculture. They consist of a tensioned track that runs on smooth rubber wheels, generating tractive force through the friction between the drive wheels and the track’s roller path.

BENEFITS

- Simplicity: Friction drive tracks have a straightforward design with fewer components, resulting in a relatively simple and cost-effective system.

- Durability: These tracks tend to have a longer lifespan due to less adverse contact between the components.

DRAWBACKS

- Lack of traction: Friction drive tracks can lose internal traction when moisture levels are high, making it difficult to maintain forward direction or steer in wet conditions.

- Ballasting issues: Balancing the front-to-rear weight distribution can be challenging with cyclically loaded equipment, requiring careful ballasting.

POSITIVE DRIVE

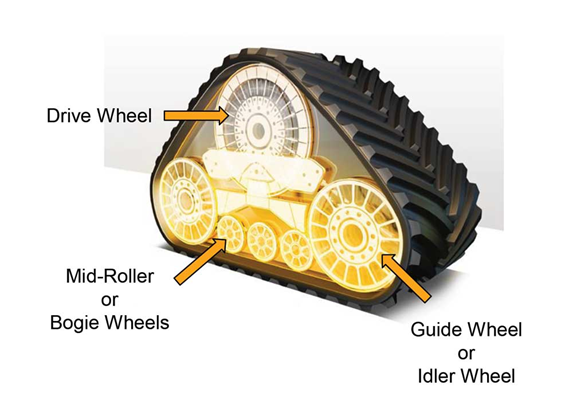

Positive drive tracks are also primarily based on friction drive, but with the addition of metal sprockets interlaced with rubber blocks. When the friction drive is overwhelmed, the sprockets engage with the rubber blocks for a positive and secure connection.

BENEFITS

- Increased torque: Positive drive tracks provide more torque to the ground in difficult or high-traction situations, making them suitable for challenging terrains.

- Better control: These tracks offer improved control and manoeuvrability, especially in wet or slippery conditions, as the drive wheel engages with the track drive lugs to prevent slippage.

DRAWBACKS

- Reduced lifespan: Positive drive tracks typically have a shorter lifespan compared to friction drive tracks due to the reliance on the drive lugs, which are more prone to damage from alignment issues, material ingestion, or excessive pulling.

- Undercarriage problems: Positive drive tracks may face more challenges with the undercarriage, leading to increased maintenance and potential issues.

Choosing between friction drive and positive drive tracks depends on the specific application’s requirements and considerations. Friction drive tracks offer simplicity, durability, and fewer undercarriage problems, while positive drive tracks provide increased torque and better control in challenging terrains. However, friction drive tracks may struggle in wet or slippery conditions, while positive drive tracks have a shorter lifespan and higher cost in terms of engagement precision. It’s essential to weigh the pros and cons of each system against the specific needs and budget to make an informed decision.

Remember, both track types have an integrally wound main cable and rubber outer drive lugs for traction. They also feature a smooth roller path and incorporate layers of steel and synthetic fabrics for strength in various applications. By considering these factors and evaluating the advantages and disadvantages, you can determine which track system will best suit your agricultural equipment needs.

If you need assistance in determining which track system is best for your agricultural equipment, please don’t hesitate to contact us at 1300 198 686 or send an email to contact@strydertrack.com. Our team will be happy to provide you with expert advice and guidance to help you make the right choice.